5 Myths About Glass Door Refrigeration

Refrigeration is one of the hardest working pieces of equipment in any commercial kitchen, operating 24/7 all year round. It is also potentially one of the most disruptive to your business if things go wrong.

A quality piece of commercial refrigeration equipment which is properly maintained can provide you with many years of efficient and trouble-free service, but no product is completely “maintenance free”.

In this article, we take a look at one of the most essential pieces of commercial refrigeration maintenance which all operators need to be aware of.

Contents:

Surprisingly, one of the most common causes of commercial refrigeration failure is a blocked condenser. The good news is, it’s easily avoidable if you make it part of your routine maintenance schedule.

Regular cleaning of this component is essential, and is a responsibility of the operator, not something which any product warranty covers.

The cost of any service callout, labour, and required replacement parts will be chargeable to the user, so is something you need to know about and act upon.

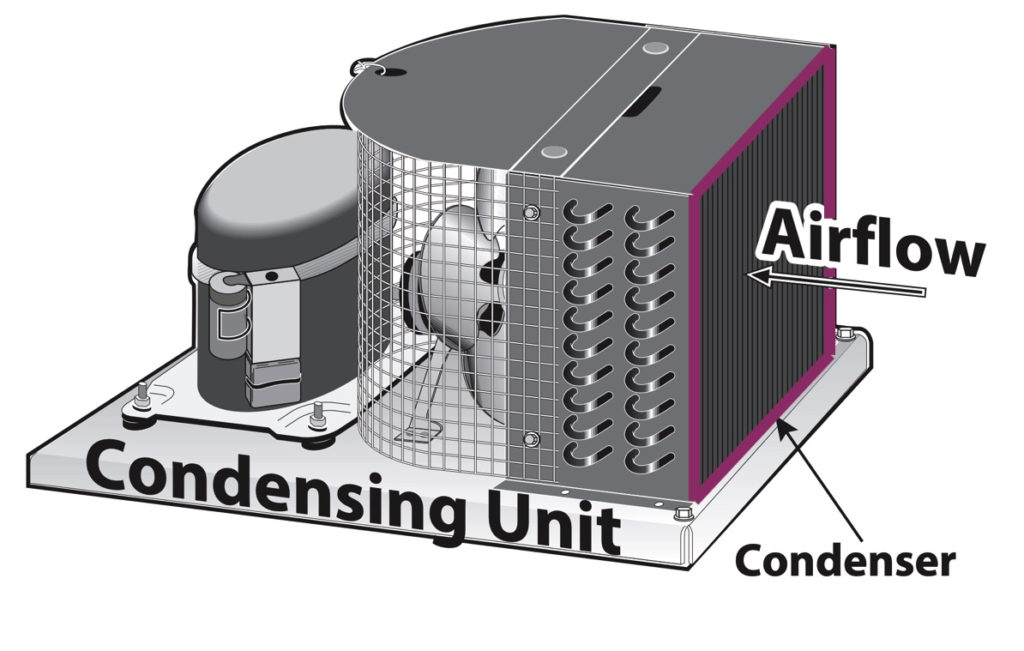

The surface of the Condenser Coil looks like a box filled with thin metal fins.

The function of the condenser coil on a commercial refrigerator is to cool and condense the refrigerant. This works by using a fan to draw in ambient outside air from around the cabinet.

As a result, dust, debris and grease can also be drawn in during this process, building up over time to restrict and eventually block the surface of the coil.

An obstructed condenser coil can cause a refrigerator to consume much more energy, as the compressor runs longer and more intensely, struggling to draw in enough external air.

Without regular cleaning, this can lead to significantly increased energy bills, reduced component life and eventual failure of the cabinet.

The condenser coil can be located in different places depending on the product and manufacturer, so the method of accessing it varies:

Visit our literature page here to find the right manual for your piece of equipment.

We recommend you clean the surface of the coil every 30 days. But in reality, how often restrictive blockages can build up varies greatly from site to site.

A pizzeria or bakery using a lot of flour, for example, may find that they require more frequent cleaning, as the powder can be easily drawn in.

In basic terms, the process of cleaning the coil involves removing the build-up of dust and debris from the fins with a stiff bristle brush, vacuum cleaner or pressurized air.

Detailed step-by-step information on accessing and cleaning the surface of the coil on your specific refrigerator (and other recommended maintenance tasks) should be available from the manufacturer.

For True customers, this information can be found in the hardcopy Operations Manual supplied with the product, or the electronic copy available on our website.

Alternatively, you can watch the clips below on how to clean the coils on our upright and undercounter refrigeration:

We also have additional videos on preventative maintenance, which can be found here.

Along with cleaning the condenser coil, other tasks such as regular interior/exterior cleaning, and assessment of consumable items, like door gaskets, should be part of your routine maintenance schedule.

For larger sites and estates, we recommend a maintenance service contract offered by many refrigeration service companies.

It is proven that routine maintenance plans can cost a business much less than relying on emergency call outs each time problems do arise. They also reduce downtime, save electricity through more efficient operation, and extend the life of kitchen equipment.

As a blocked condenser is not covered by any manufacturer’s warranty policy, it’s your prerogative to investigate and understand the terms you are getting and agreeing to when buying any new piece of equipment with a warranty.

Most refrigeration equipment bought new from a supplier will have some warranty provision, typically one to two years parts and labour. However, what is and isn’t included in this coverage can vary significantly between manufacturers.

If anything isn’t transparent or fully understood, seek clarification from the manufacturer before making the purchase decision. Only with this information are you able to make a fully informed and confident equipment choice.

At True, we have the product confidence to offer a five-year parts and labour warranty across our entire range, which we believe is the most inclusive and comprehensive in the industry.

Full terms, conditions and exclusions of our warranty coverage can be found in our policy document here.

In our 75 years of developing commercial refrigeration equipment, we have been at the forefront of innovation and technology development, and as a result, our products contain many patented designs and features which you can only find on True fridges.

One of these patented features is True’s Reverse Condensing Unit (RCU), which periodically reverses the rotation direction of the condensing fan to help “blow out” some debris from the surface of the condensing coil, assisting operators in their maintenance effort.

Watch the video below to find out more about our RCU technology.

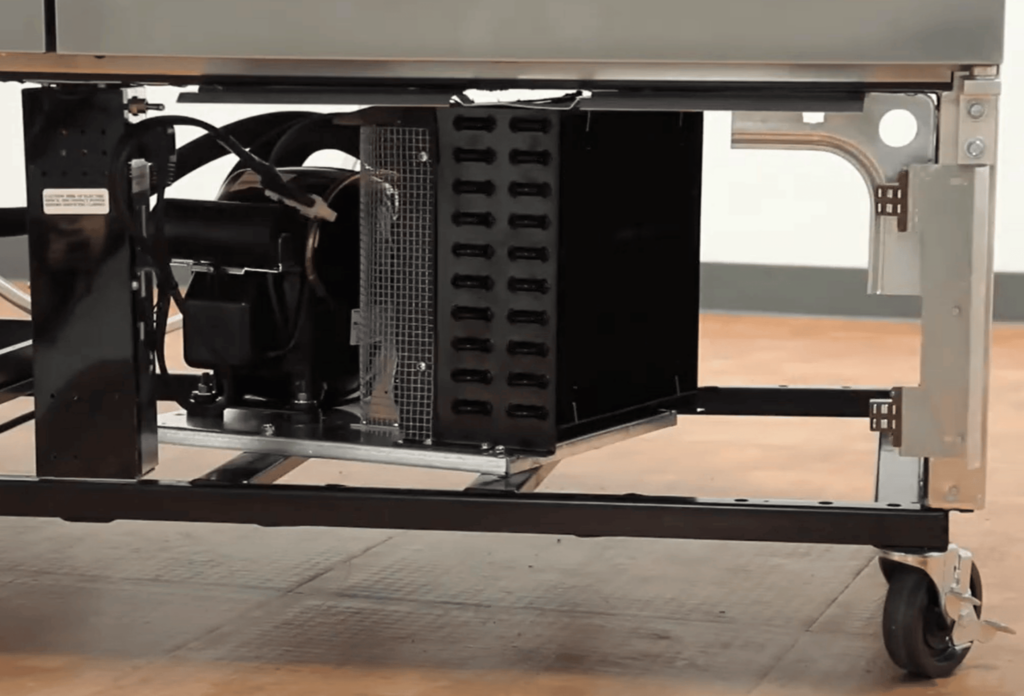

Unlike most other manufacturers, True champion the use of a “bottom-mount” design on our uprights, where the compressor and condenser components are housed in the bottom section of the cabinet, rather than the top.

Not only does this make the condenser coil more easily accessible for cleaning, but compressors naturally perform more efficiently in the coolest, most grease-free area of the kitchen, and since heat rises, this usually means lower is better.

It isn’t the easiest way to manufacture a refrigerator, requiring more piping between the components on the bottom and evaporator at the top, but we believe it results in a better product.

With True, you are not just purchasing a refrigeration unit; you are investing in innovation, superior design and unparalleled warranty coverage.

Ensure your investment is protected and enjoy the peace of mind that comes with choosing True.